JUMP TO: Cleanroom Definition | Video: What is a Cleanroom? | What is a Modular Cleanroom System? | Cleanroom ISO Standards | What are Cleanrooms Used For? | What Does a Cleanroom Look Like? | Today's Definition of a Cleanroom

What is a Cleanroom?

Cleanroom Definition: A cleanroom is an enclosed space within a facility, designed to control airflow, pressurization, temperature, and humidity. This environment ensures the critical conditions required for specific processes or product protection from particulates.

Cleanrooms have traditionally been used by industries such as pharmaceuticals, biotechnology, life sciences, microelectronics, and food packaging to protect products or processes from contamination. Contaminants include dust, vapors, microbes, and particles from people and materials. Today, cleanrooms are utilized in a wide range of environments to control all contaminants and ensure product quality, worker safety, or research integrity.

Video: What is a Cleanroom Environment?

As companies strive to maximize product yield, enhance quality control, and ensure safety, the demand for cleanrooms or controlled environments is growing across various industries. Once used to high-tech semiconductor manufacturing and university research labs, Cleanrooms are now essential in many fields. But what exactly is a cleanroom? This is an introductory video that covers what a Cleanroom is, Cleanroom design, Cleanroom construction, contamination, and Cleanroom ISO classification.

A Modular Cleanroom System is a prefabricated, customizable Cleanroom solution that offers flexibility, scalability, and cost-effectiveness. These systems are constructed using modular components, allowing for quick and clean installation and easy reconfiguration or expansion as needs change. Modular Cleanrooms can be tailored to meet specific cleanliness classifications and environmental control requirements, making them suitable for a variety of industries and applications.

Advantages of Modular Cleanroom Systems:

- Flexibility & Portability

- Quick & Clean Installation

- Cost-Effective & Tax Advantages

- Standard & Custom Pre-engineered Solutions

Cleanroom ISO Standards

To achieve the required environmental conditions, air in a Cleanroom is purified using High Efficiency Particulate Air (HEPA) filters. Air filtration systems vary based on the required cleanliness level. Cleanrooms are classified based on the number and size of airborne particles per cubic meter of air, as per ISO 14644-1 standards:

ISO 1: Max 10 particles ≥0.1 µm

ISO 2: Max 100 particles ≥0.1 µm

ISO 3: Max 1,000 particles ≥0.1 µm (Class 1 Cleanroom)

ISO 4: Max 10,000 particles ≥0.1 µm (Class 10 Cleanroom)

ISO 5: Max 100,000 particles ≥0.1 µm (Class 100 Cleanroom)

ISO 6: Max 1,000,000 particles ≥0.1 µm (Class 1,000 Cleanroom)

ISO 7: Max 10,000,000 particles ≥0.1 µm (Class 10,000 Cleanroom)

ISO 8: Max 100,000,000 particles ≥0.1 µm (Class 100,000 Cleanroom)

ISO 9: Room air

What Are Cleanrooms Used For?

Cleanrooms serve critical roles across industries to ensure product quality, safety, and compliance with regulatory standards. Here are some key applications:

- Pharmaceuticals and Biotechnology: Cleanrooms are essential for the manufacturing of medications, vaccines, and biotechnology products to prevent contamination and ensure product purity.

- Microelectronics and Semiconductor Manufacturing: These environments are crucial for producing microchips and electronic components where even the smallest particles can cause defects.

- Aerospace and Defense: Cleanrooms are used to assemble and test spacecraft, satellites, and other high-precision equipment to avoid contamination that could affect performance.

- Healthcare and Medical Devices: Cleanrooms ensure the sterile production of medical devices, surgical instruments, and diagnostic tools.

- Food and Beverage Packaging: These controlled environments help maintain hygiene and safety standards in food processing and packaging.

- Automotive: Cleanrooms are used in the production of sensitive automotive components such as sensors and electronics to ensure high reliability and performance.

- Research and Development: Cleanrooms support various R&D activities in universities and private research institutions, particularly in fields like nanotechnology and life sciences.

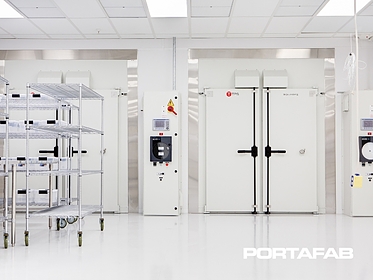

What Does a Cleanroom Look Like?

Cleanrooms are highly controlled environments that have a distinct appearance characterized by their design and sterile conditions. Here's what you can typically expect to see in a Cleanroom:

- Smooth, Non-Porous Surfaces: Walls, floors, and ceilings are made from materials that are easy to clean and do not shed particles. Common materials include coated steel, aluminum, or specialized polymers.

- HEPA Filters and Airflow Systems: Cleanrooms are equipped with HEPA filters that purify the air, often visible in the ceiling. The air flows in a controlled manner, either in a single pass or recirculating system.

- Minimalistic Interior: The interiors are kept simple and uncluttered to reduce the number of particle-generating surfaces.

- Gowning Areas: Adjacent to the main Cleanroom area, there are gowning rooms where personnel put on protective clothing such as gowns, gloves, masks, and hairnets to minimize contamination.

- Pressure Differentials: To maintain cleanliness, Cleanrooms often have airlocks and maintain positive pressure differentials, ensuring that air flows out of the Cleanroom rather than allowing contaminated air to enter.

- Controlled Lighting: Lighting is usually bright and uniformly distributed to avoid creating shadows.

- Monitoring Systems: Various sensors and monitoring devices are installed to continuously measure environmental parameters such as particle count, temperature, and humidity.

Today's Definition of a Cleanroom

Today, "Cleanroom" often describes any area with environmental controls. "Controlled Environments" are areas where particulates, temperature, pressure, static, humidity, or other elements are managed without adhering to specific cleanroom standards.

Whether you need an ISO 3 cleanroom for advanced research or a controlled environment for manufacturing processes, PortaFab builds Modular Cleanroom Systems to your requirements. Contact us to learn more.