FabLine modular cleanroom wall systems make it easier and more cost-effective than ever before to create ultra-clean facilities meeting the critical environmental conditions demanded in precision microelectronics manufacturing.

For The Most Demanding Cleanroom Requirements

Designed primarily for the microelectronics and nanotech industries, FabLine systems are ideal for applications with significant bulkheading requirements or environments that require non-outgassing, non-shedding, and anti-static wall systems.

- Extensive Bulkheading Flexibility

- Support for Process/Utilities

- Batten System for Interior Partitions

- Gasketing Options

- Anti-static Wall Panels

- Furring Walls

A Total Cleanroom Wall System

The PortaFab FabLine Series includes three wall systems for Framing, Batten, and Furring applications. Pre-engineered wall panels are interchangeable within all three systems, for consistent appearance, easier inventory and faster installation.

Engineered for use in any Class modular cleanroom, FabLine wall panels are non-outgassing, non-particle shedding and anti-static, decreasing product contamination.

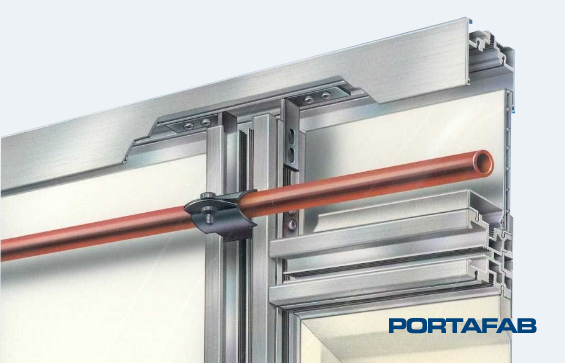

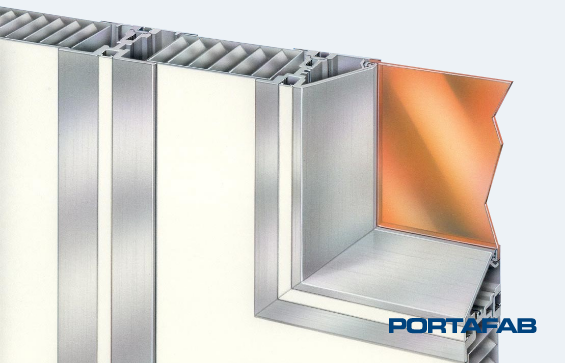

FabLine Framed Wall Systems

Provides the perfect combination of high durability, design versatility and simple installation, especially around tools and bulkheading equipment.

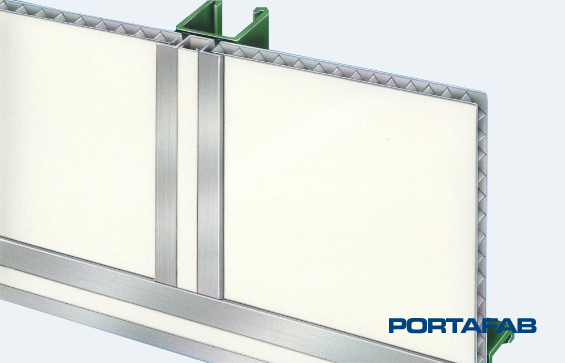

FabLine Batten Wall System

A cost-effective alternative to Framed Systems for areas which do not require extensive bulkheading, but can benefit from a double-flush surface partition system.

FabLine Furring Wall Systems

FabLine Furring Wall Systems offer an attractive, cost-efficient wall system for installation over existing block or gypsum walls, drywall studs, and columns.