Enclosing paint systems is not only important for containing the paint and fumes from the painting process. It is also imperative to keep dirt and debris out of the area in order to not ruin paint jobs.

Modular Paint System Enclosures

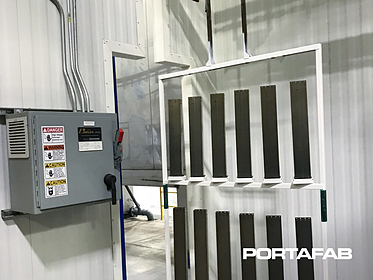

PortaFab's cleanroom systems are often modified for the paintings and coatings industry because they offer the benefits of modular building with the controlled conditions of a cleanroom. PortaFab walls can also accommodate custom conveyor openings and be easily moved to expand or move equipment in and out of completed units.

Case Studies

Case in Point #1

Suzuki required the use of PortaFab's Omni wall system in order to enhance its existing paint line process, and improve operations. The wall system would function as a protective barrier around the Suzuki paint process machinery, keeping other equipment and personnel safe from its powder coat applications. Suzuki had strict requirements for the wall system that would be used for this paint booth enclosure. The benefits provided:

- Insulated walls for optimal thermal control

- Improved product yield

- Integration with existing conveyor system

Case in Point #2

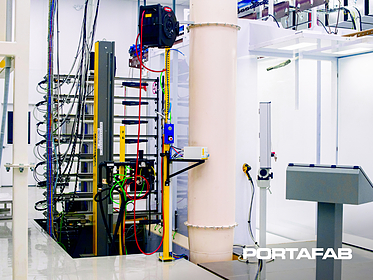

Bobcat is a known leader in the design, manufacture, marketing and distribution of compact equipment for construction, rental, landscaping, agriculture, grounds maintenance, government, utility, industry and mining. In order to maximize operational efficiency, our client required the installation of an environmental room at their headquarters in order to contain the processes and equipment used in paint finishing and coating applications. The benefits provided:

- Effective environmental control

- Timely installation with minimal disruption to plant

- Met 24’ height requirements

Contact PortaFab Today

To receive a quote for a cleanroom application, or to speak with a local PortaFab cleanroom contractor, click one of the links below. For more information regarding cleanrooms and cleanroom applications, follow this link - Cleanroom Applications.